Introduction

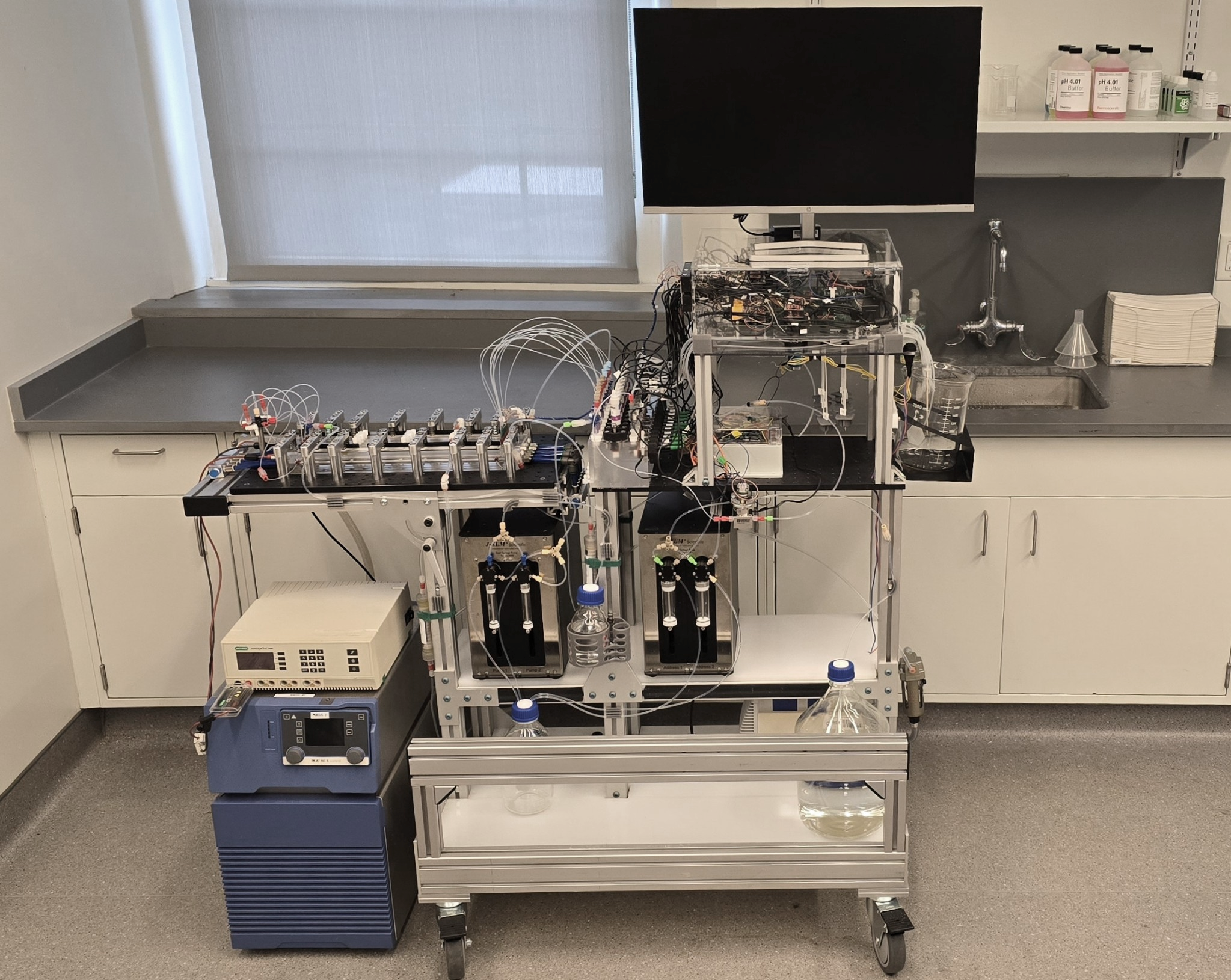

Founded in 2017, Enquyst is an innovative bioprocess and analytical technology company that is on a mission to disrupt the multi-$bn bioprocess equipment market.

We are developing best-in-class equipment and processes change the definition of purity and dramatically broaden the access of the best biotherapeutics to the global patient population.

To achieve this mission, we have developed innovative process technologies that address some of the most pressing challenges in the manufacturing of diverse classes of biotherapeutics.

Today’s Medicines Are Being Produced with Yesterday’s Technologies

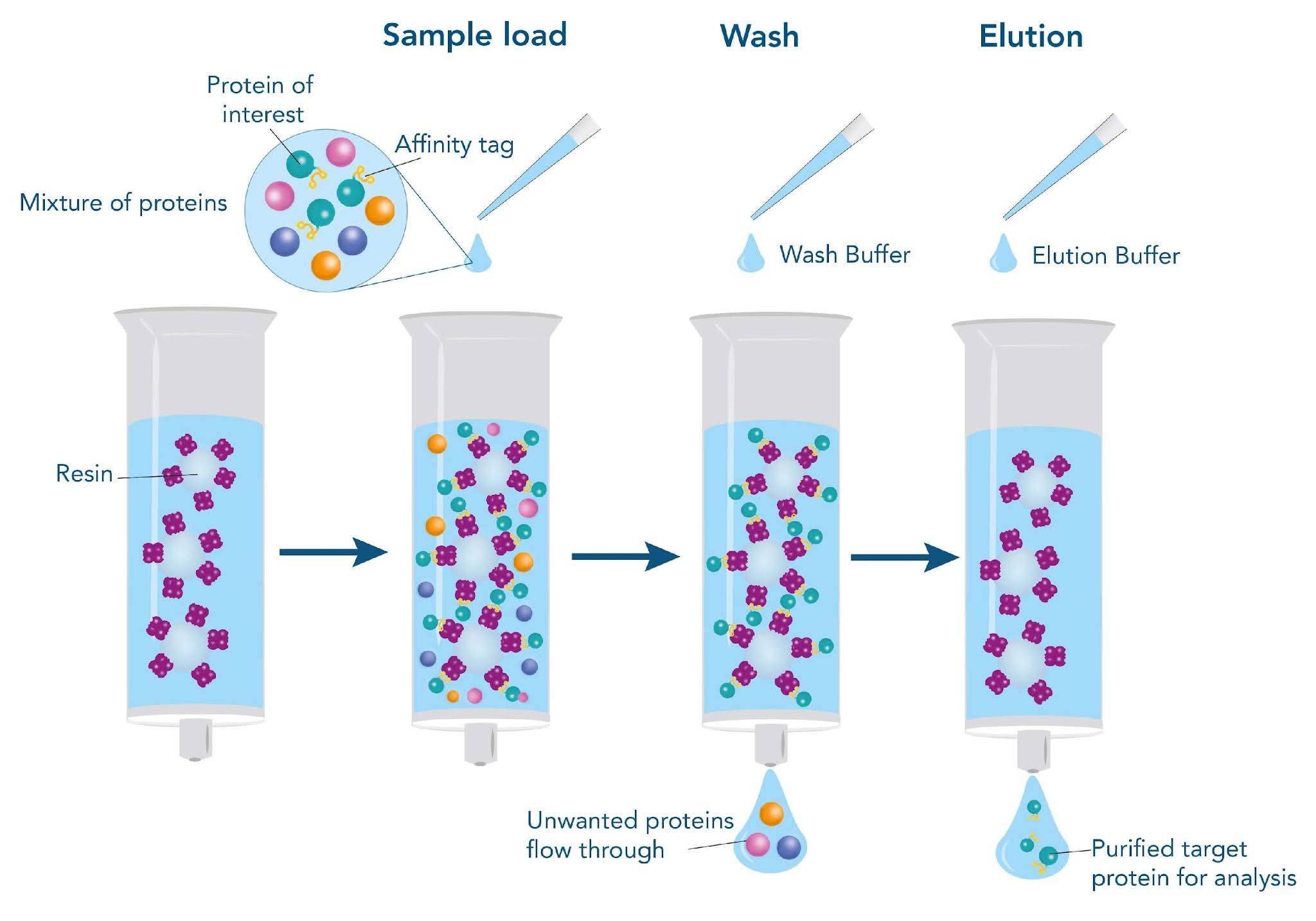

Over the past few decades, innovation in bioprocessing has been slow to non-existent, predominantly because of a reluctance to move away from the familiarity of chromatography derived from its widespread use in monoclonal antibody manufacturing. Thus, innovation has been limited to changes targeting incremental improvements of these existing chromatography technologies. The problem with this is that chromatography is not capable of meeting the purification demands of the growing diversity of the biological medicines of today and the future.

2019-01-01

Depth Filtration

2020-01-01

Protein A Chromatography

2021-01-01

Viral Inactivation

2021-01-01

Cation Exchange (CEX) Chromatography

2021-01-01

Anion Exchange (AEX) Chromatography

2021-01-01

Viral Filtration

2021-01-01

UF/DF

Disruptive Integrated Downstream Processing Platform

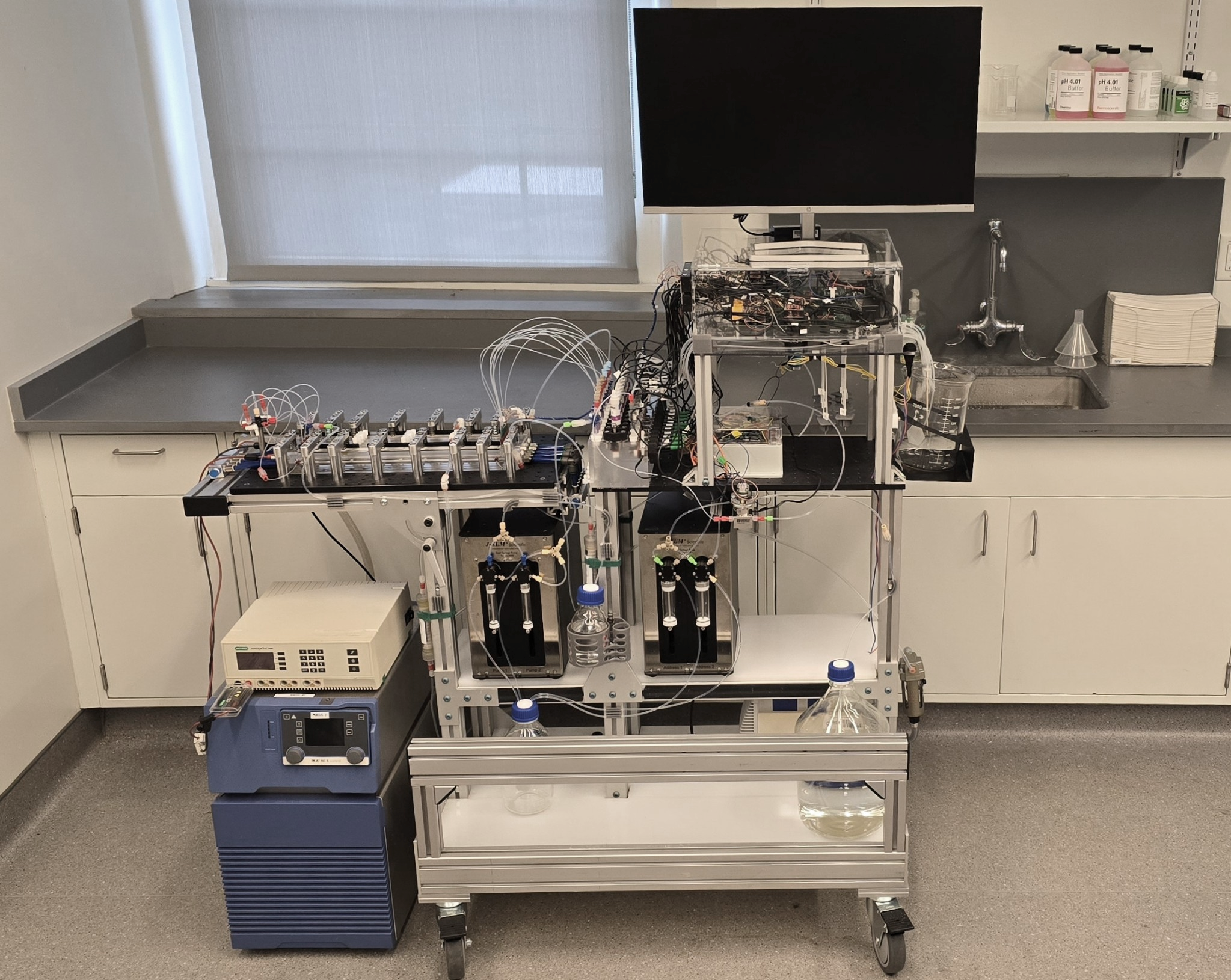

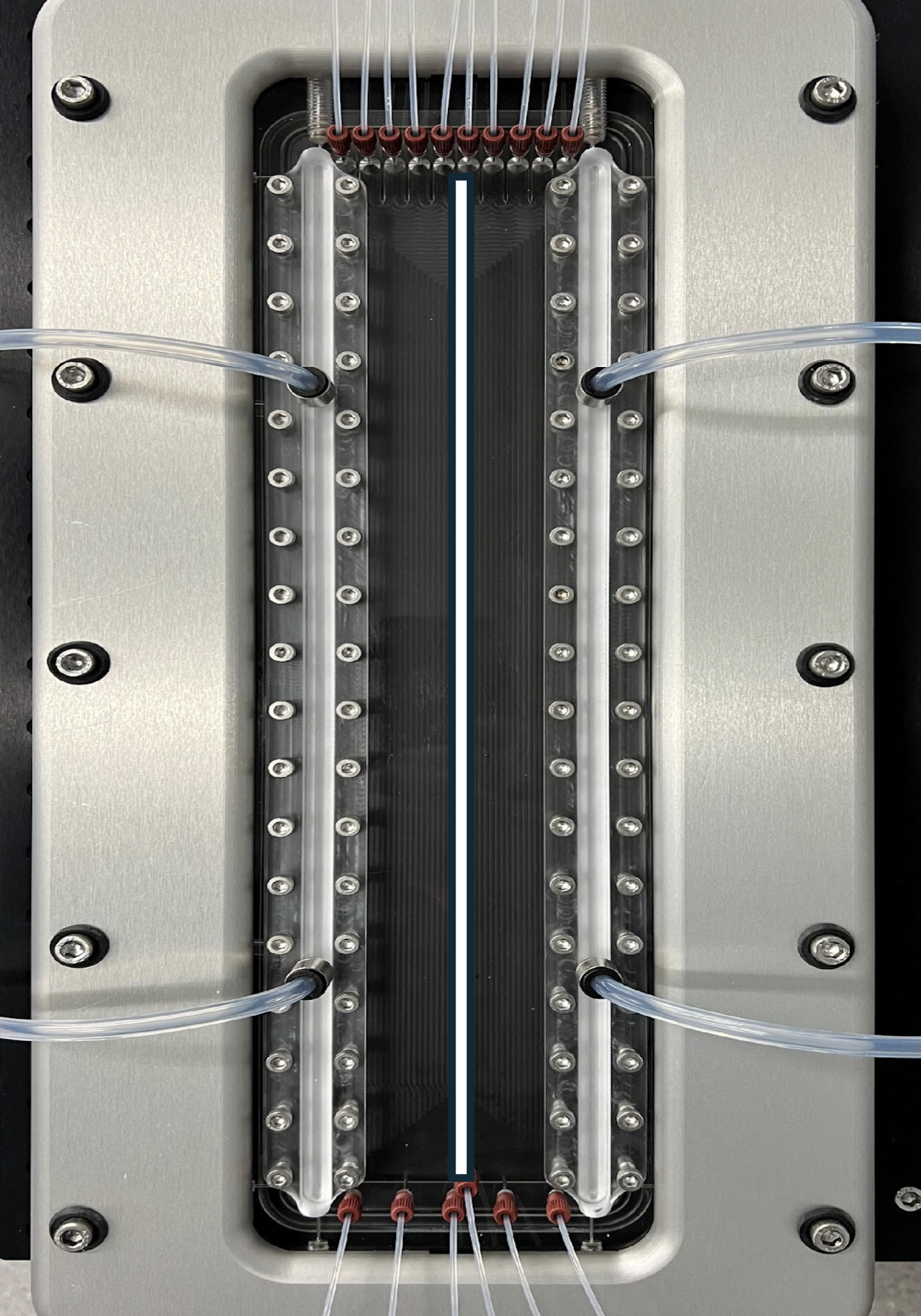

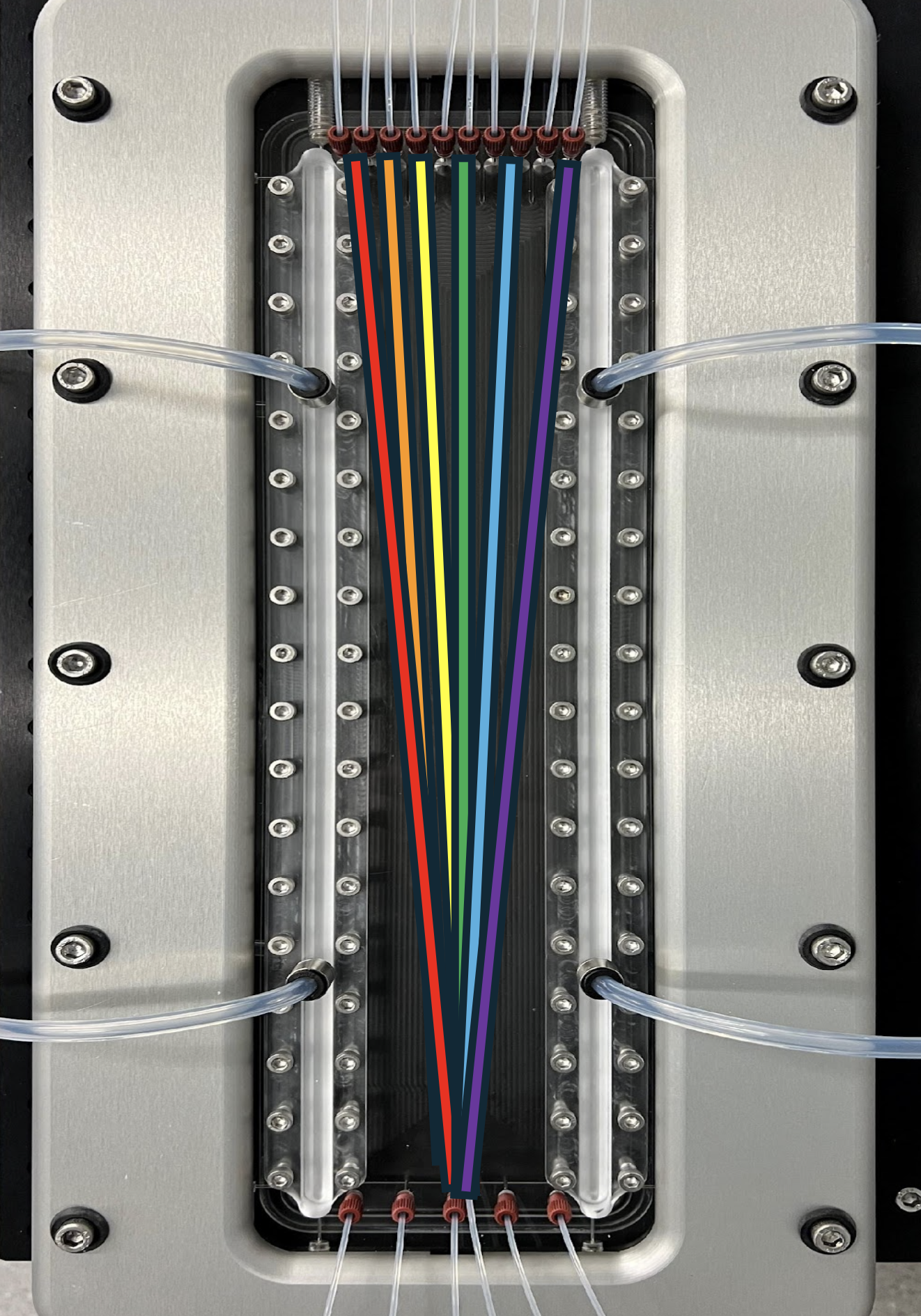

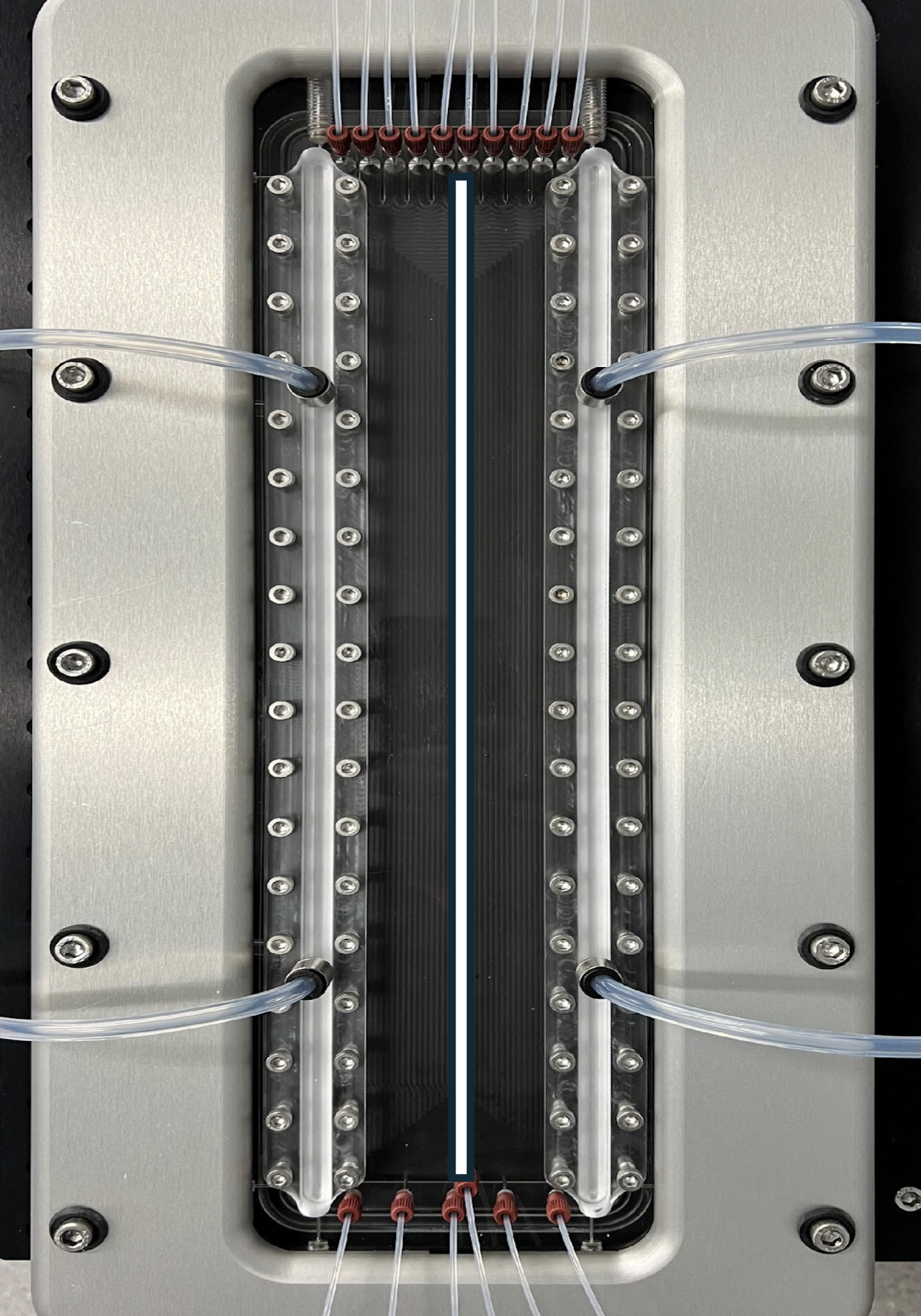

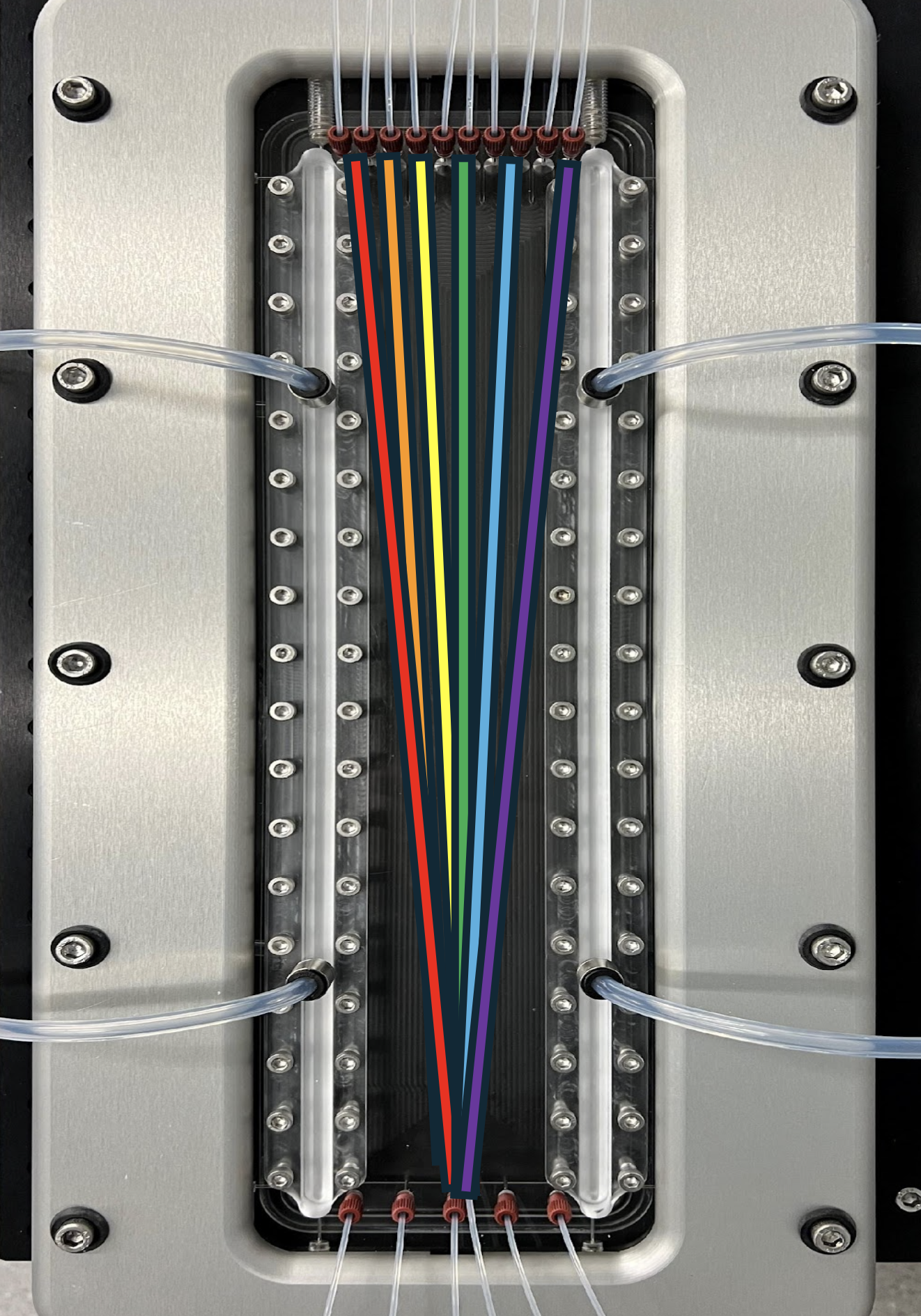

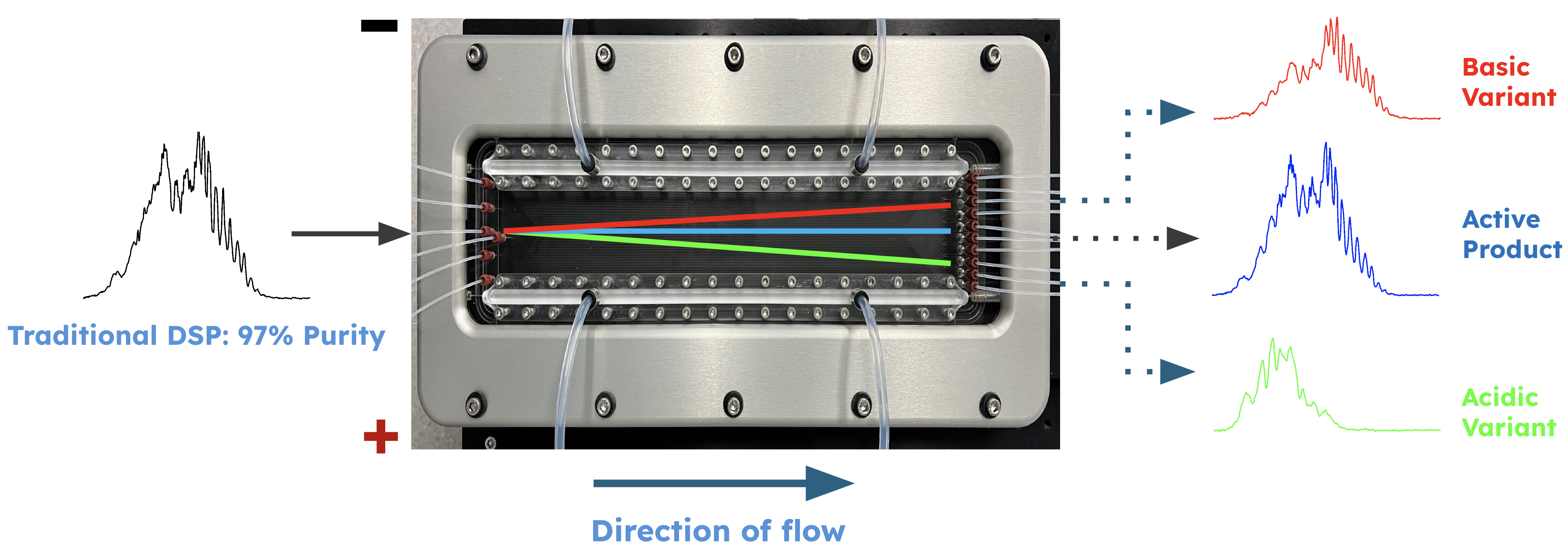

Enquyst’s patented Isoelectric Point Purification (IPP) technology is a flow-through purification technology that separates without relying on a target biomolecule’s interaction with a surface, matrix, or resin (e.g. resin-free). Using only chemistry, physics, and fluid dynamics, the IPP technology isolates and purifies a target biomolecule by exploiting its true biophysical fingerprint, specifically, the combination of its isoelectric point, its charge heterogeneity in a complex mixture, and its molecular size. Capitalizing on its flow-through nature, Enquyst’s IPP technology has demonstrated the ability to obtain ultra-high purity without yield loss.

Purifying Biomolecules with Chemistry, Physics, and Fluid Dynamics

Disruptive Integrated Downstream Processing Platform

Enquyst’s patented Isoelectric Point Purification (IPP) technology is a flow-through purification technology that separates without relying on a target biomolecule’s interaction with a surface, matrix, or resin (e.g. resin-free). Using only chemistry, physics, and fluid dynamics, the IPP technology isolates and purifies a target biomolecule by exploiting its true biophysical fingerprint, specifically, the combination of its isoelectric point, its charge heterogeneity in a complex mixture, and its molecular size. Capitalizing on its flow-through nature, Enquyst’s IPP technology has demonstrated the ability to obtain ultra-high purity without yield loss.

Purifying Biomolecules with Chemistry, Physics, and Fluid Dynamics

A New Definition of Pure

Enquyst’s IPP technology enables ultra-high purity polishing of traditional biotherapeutics to create a new standard in purity. Purity is no longer about %...it’s now about what species in a pure product are efficacious and which may cause undesired side effects. This new level of purity has the ability to give new classes of life-changing therapies a viable path to the clinic.

Cost Savings with Enquyst IPP Technology Implementation

Replacement of ProA, CEX & AEX Chromatography Unit Operations with IPP Technology

0%

0%

0%

Reduction in total COGS for DSP

Increase in yield

Reduction in total single use media bags per batch

Cost Savings with Enquyst IPP Technology Implementation

Replacement of ProA, CEX & AEX Chromatography Unit Operations with IPP Technology

0%

Reduction in total COGS for DSP

0%

Increase in yield

0%

Reduction in total single use media bags per batch

Applications

Explore how Enquyst’s IPP technology empowers the discovery, development and production of advanced therapies, from monoclonal antibodies and therapeutic proteins to mRNA and viral vectors for gene therapies.

Monoclonal Antibodies

Bispecific Antibodies

Antibody Drug Conjugates

Viral Vectors

mRNA & Lipid Nanoparticles

Viruses

Plasmid DNA